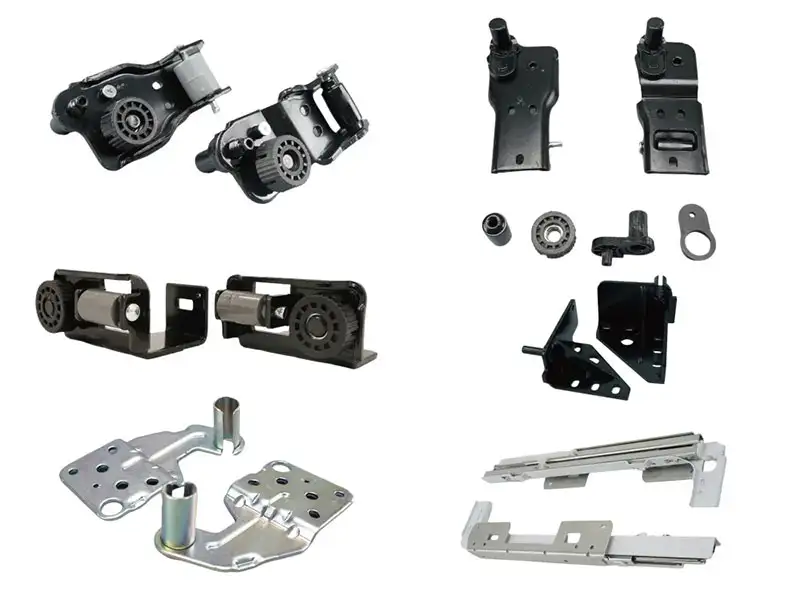

JCV specializes in integrated slide rail manufacturing, combining stamped metal components with plastic guides for smooth-gliding appliance mechanisms. As certified suppliers to Haier & Casarte, we deliver ±0.05mm tolerance drawer systems for refrigeration applications.

Custom Development Process

1.Design Input

Accept 2D/3D formats:CAD: SolidWorks/Inventor/UG; Vector: DXF/DWG; Sample 3D scanning

2.Engineering Analysis

- Unfolding of metal parts

- Shrinkage compensation program for plastic parts

- Assembly gap simulation report

3.Prototype Validation

Metal stamped parts: Continuous mold prototyping

Plastic guided parts: 48hr 3D rapid prototype

Functional Test: 5-direction force simulation

4.Mass Production

80-ton Press stamping

650-ton injection molding

error-proof assembly

[Request Precision Quote]

Please provide the following information:

✓ Material Thickness/Weight

✓ Annual demand (mold cost sharing program)

✓ Surface treatment

✓ Packaging Special Requirements

✓ Test standard

25 years of home appliance parts manufacturing experience, support the signing of drawing confidentiality agreement, provide the first sample inspection report.

| Name | Amount | Table Travel(mm) |

| CNC Machining | 4 | 850 |

| CNC Machining | 1 | 1060 |

| CNC Machining | 1 | 1580 |

| CNC Machining | 1 | 5250 |

| CNC Machining | 2 | 4223 |

| CNC Machining | 3 | 3160 |

| CNC Machining | 2 | 2150 |

Keywords

PREVIOUS:

NEXT:

Precision Slide Rail Assembly Metal Fabrication Solutions

Contact Us

Classification