Custom Tooling Design & Production

To expedite your mold design and tooling service request, please provide:

- Product drawings/samples

- Industry application (automotive, electronics, medical, etc.)

- Annual volume or batch quantities of Parts

- Target production region

- Special material/performance requirements

- New product development or existing product optimization

Our engineering team will analyze your requirements and provide a competitive quotation within 24 working hours.

Quality Assurance:ISO-Certified Mold Standard Management System

Advanced Tech:3D CAD/CAM/CAE Integrated Solutions + Smart Manufacturing Systems

Quality Assurance:ISO-Certified Mold Standard Management System

Global Support:Dedicated project teams in North America, EU and APAC regions

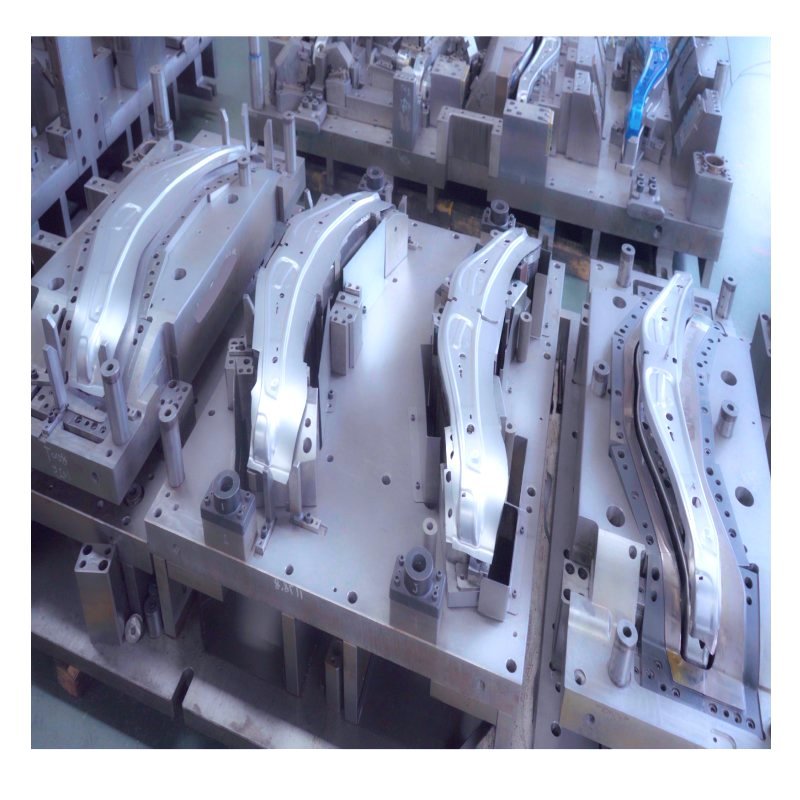

Your Precision Manufacturing Solution Partner in Dies & Moulds

Why Invest in Mould Solutions

Precision Engineering

The appearance, accuracy of the dimensions, reliability, and productivity of the plastic and metal parts depend on the design and quality of the mold.

•Optimal dimensional accuracy <±0.01mm

•Enhanced product consistency

300,000~500,000Cycle life-30%+ longer tool lifespan

Cost Efficiency

The cost of ordering high-quality molds is more than compensated for during their lifetime: equipment downtime is minimized, energy and funds are not being spent for repairs and debugging.

•Reduce 40%+ downtime

•Minimize material waste <2%

Energy-saving production workflows

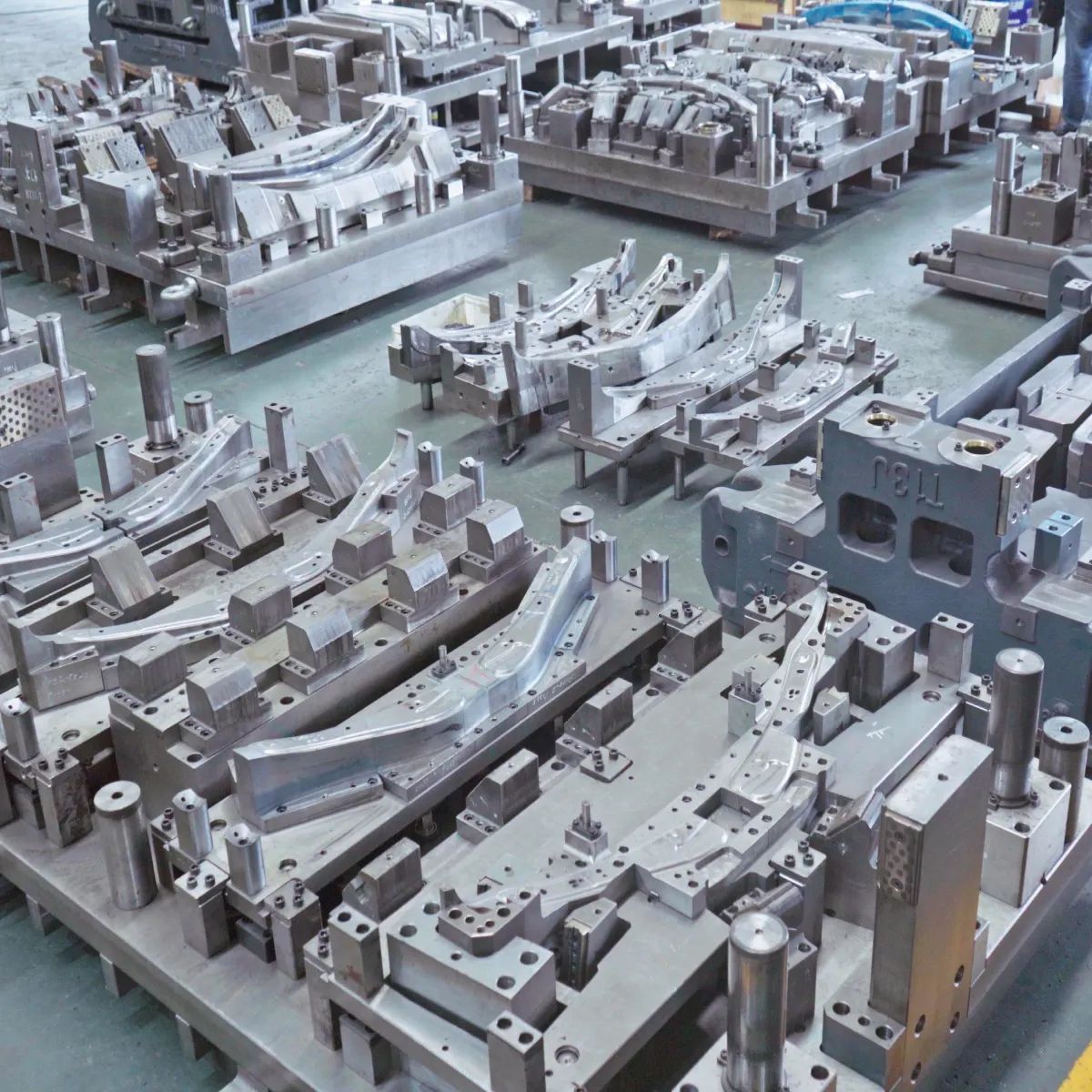

Why Choose JCV's Tooling Design

JCV Precision Manufacturing delivers customized mold solutions that optimize your production costs through intelligent tooling design and precision CNC machining. Our DFM-driven approach ensures 98%+ first-pass success rate in molding trials.

End-to-End Custom Mold & Die Process

We provide one-stop service from mold design and manufacturing to mass production.

Step 1

Confirm the parts specifications

Step 2

Confirm the parts specifications

Step 3

Confirm DFM analysis report

Step 4

Confirm 3D Mold design and review

Step 5

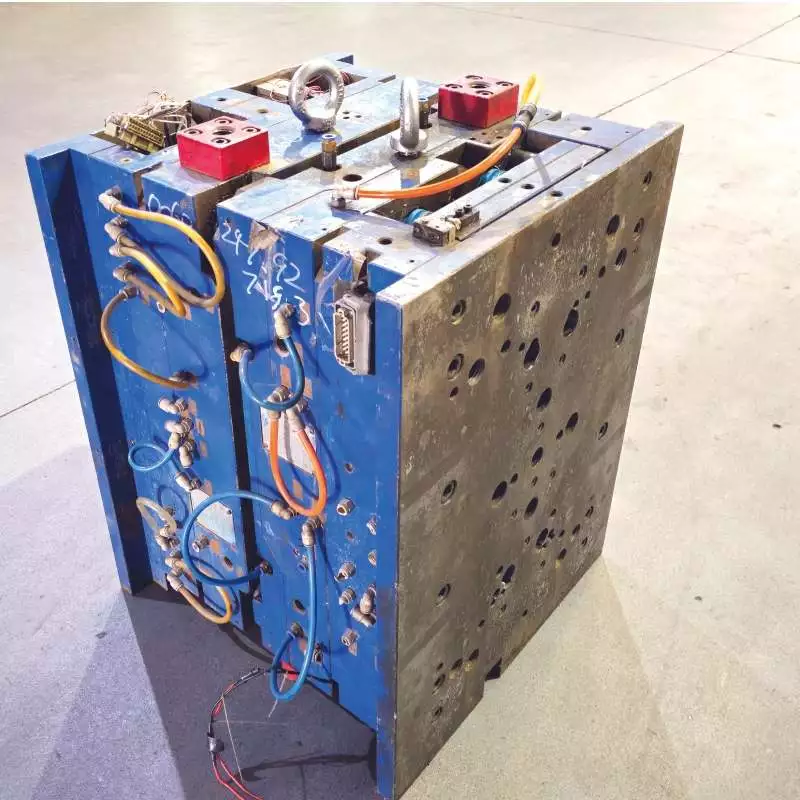

Material procurement and manufacturing

Step 6

Mold trial validation

MOLD QUALITY CONTROL

More Than 24 Year’s Experience

Qualified person with continuous training in measurement systems.

Regularly review the quality system.

Periodical certifications of measurement equipments.

Raw Material Certification

Surface Finish Analysis

In-Process Dimensional Checks

T1 Sample Approval Process

Smart Manufacturing Management

Real-time Project Tracking System (ERP/MES集成)

24/7 Cross-Timezone Technical Support

ISO14001 Certified sustainable Manufacturing Practices