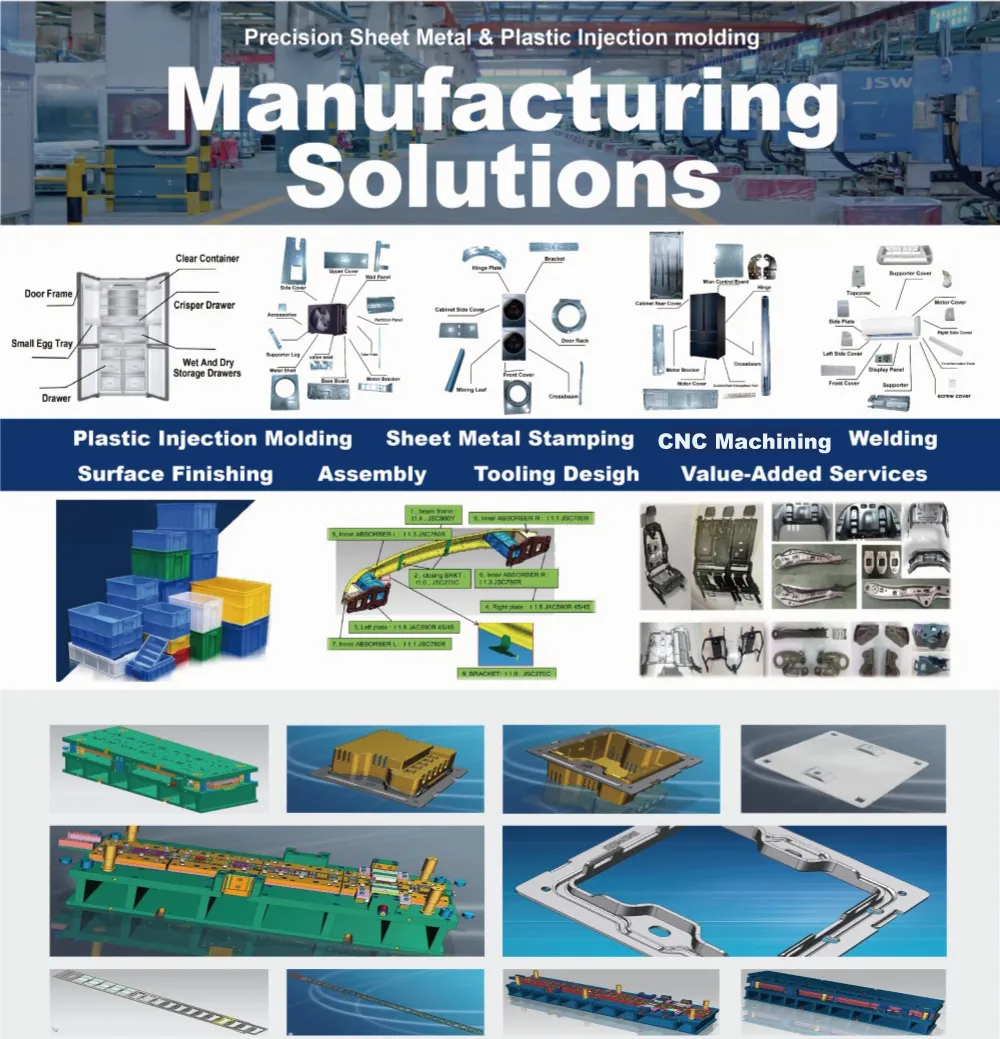

JCV Precision Manufacturing Co., Ltd. brings 25-year expertise in tooling design and mold prototyping, serving appliance, automotive, and consumer electronics industries worldwide.

Technical Capabilities

- IATF 16949 & ISO 9001:2015 certified systems

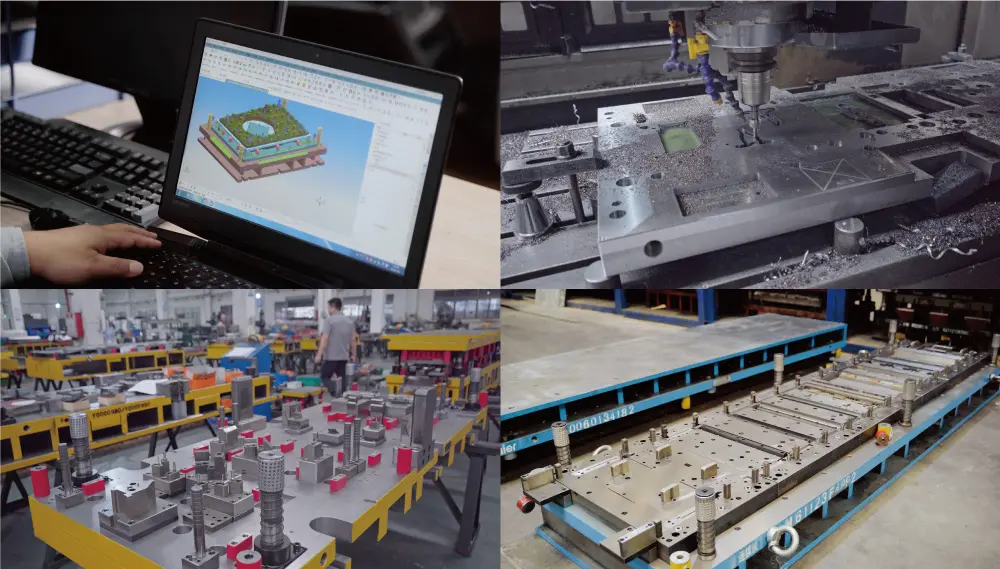

- CNC and EDM equipped workshop

- ±0.005mm tolerance mold manufacturing

- 300,000~500,000 cycles of life span

Engineering Resources

Our 30+ member technical team includes:

- Tooling Masters with 15+ years experience

- CAD/CAE Specialists (UG NX & Moldflow)

- GD&T Certified quality engineers

- Dedicated DFM analysis department

- Bilingual Project coordinators

Integrated Manufacturing Process

1. Concept Development

- 3D scanning & reverse engineering

- Material selection advisory

- Cost-breakdown analysis

2. Precision Tooling

- Multi-cavity mold construction

- Conformal cooling channels

- Vacuum heat treatment

3. Validation Protocol

- T0 sample inspection

- CMM dimensional report

- 1000-cycle stress test

- RoHS compliance verification

4. Mass Production

- Automated assembly lines

- Daily first-article inspections

- Real-time production tracking

- Just-in-time delivery system

Request free project feasibility analysis through our online portal or visit facility for live tooling demonstration.

| Name | Amount | Table Travel(mm) |

| CNC Machining | 4 | 850 |

| CNC Machining | 1 | 1060 |

| CNC Machining | 1 | 1580 |

| CNC Machining | 1 | 5250 |

| CNC Machining | 2 | 4223 |

| CNC Machining | 3 | 3160 |

| CNC Machining | 2 | 2150 |

PREVIOUS:

NEXT:

China Precision Mold Manufacturing Rapid Tooling Prototyping

With 24 years of experience in sheet metal and injection molding production.

Contact Us

Classification