Our Surface Finishing Service

JCV offers a comprehensive range of surface treatment services for both metal and plastic parts. Our 7,000㎡ facility operates 3 automated powder coating lines with annual capacity exceeding 7million ㎡. We provide one-stop service from production, treatment, packaging, and transportation solutions.

Leading Industrial Electrostatic Spraying and Surface Finishing

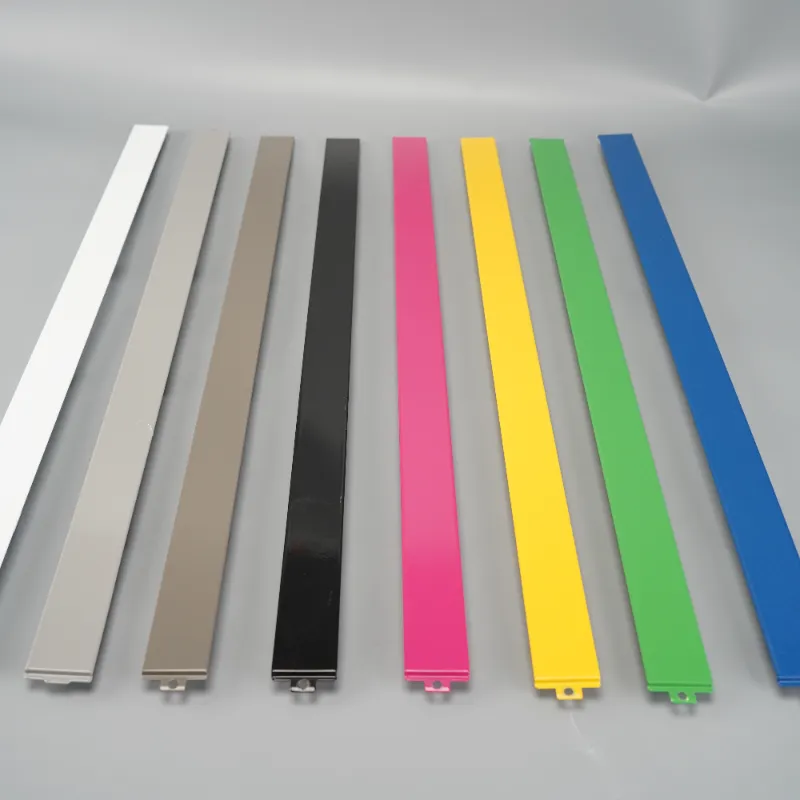

Powder Coating Service

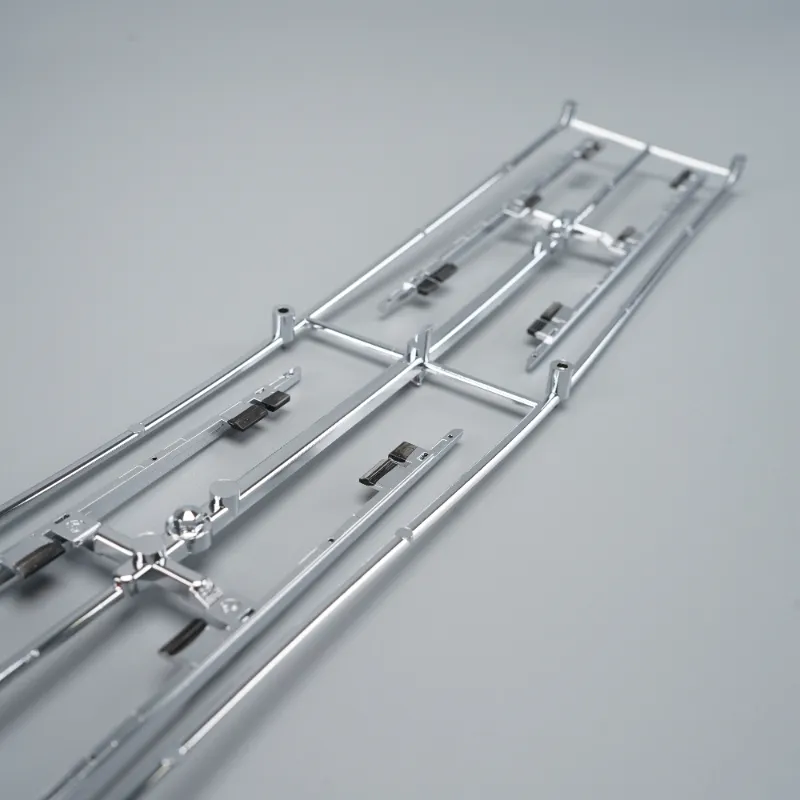

We are ISO9001 certified and have more than 24 years of experience in the electrostatic spraying of sheet metal, with 3 large electrostatic powder coating production lines, advanced technology and equipment, able to meet the coating of large parts, as well as quality and quantity to meet the simultaneous production of a variety of colors, with an annual coating capacity of more than 7 million ㎡.

We provide one-stop service from sheet metal forming, powder coating production, and finished product assembly to logistics.

Why Choose Us?

Advanced technology

A full set of surface treatment technology for metal products and advanced quality control testing equipment and devices, leading technology in the same industry.

Modern process

Adopting the Zn-Ni-Mn system phosphating process, we can paint the metal shells of household appliances, automobile parts, instrument and electric industry, metal furniture, and so on.

Large production capacity

Three large-scale coating lines, which can meet the needs of large-sized coating parts as well as the production of more than 30 kinds of colors at the same time with high quality and quantity.

One-stop service

We provide one-stop service from mold design to sheet-metal forming, powder coating, and assembly. We are capable of supplying assemblies to meet a wide range of customer needs.

OUR PRODUCTION

Our Printing Service

Laser engraving

Laser engraving technology utilizes focused light beams to create permanent markings on substrates with micron-level accuracy. Our industrial-grade systems perform surface etching, deep engraving, and decorative marking across multiple material categories including:

• Durable metals (aluminum/stainless steel)

• Engineered plastics (ABS/polycarbonate)

• Natural materials (hardwoods/leather)

• Specialty surfaces (anodized coatings/glass)

This non-contact process ensures zero material warping while achieving 0.1mm resolution for intricate logos, serial numbers, or decorative patterns. Particularly advantageous for industrial part identification, awards/trophies, and personalized consumer goods requiring FDA-compliant markings.

Digital Printing

Our advanced UV-LED flatbed printers deliver photographic-quality output (1200×1200 dpi) with expanded color gamut capabilities.

Key technical advantages include:

•Superior Adhesion - Direct printing on polypropylene, acrylic, and other engineered polymers;

•Surface Enhancement - Optional gloss/matte protective overcoating;

•Complex Geometry Handling - Up to 15mm substrate thickness accommodation;

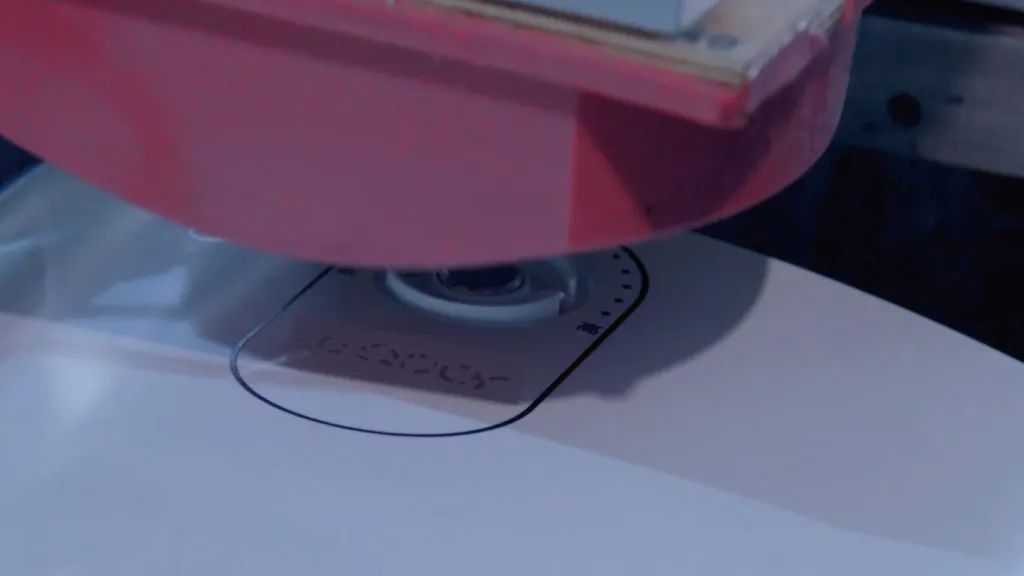

Thermal Transfer

This is a good option for custom colors and multi-color logos and images. Thermal transfer printing is limited to flat surfaces. Specializing in complex graphic reproduction through our hybrid screen+thermal transfer system:

① CMYK+Spot color screen printing on PET carrier film

② Precision thermal lamination (160-180°C)

③ Permanent adhesive bonding to substrates

Related Products

We offer a wide range of surface treatment processes, please let us know your needs!

Read More