About Our Welding Service

As a certified supplier with 26 years in advanced manufacturing, JCV Precision Manufacturing delivers precision welding services combining manual with automated robotic systems. Providing spot welding, stud welding, laser welding, and other welding services.

Our ISO-certified facility features robotic workcells and laser welding technologies compliant with AWS D1.1 standards.

JCV offers professional welding services through specialized welding facilities

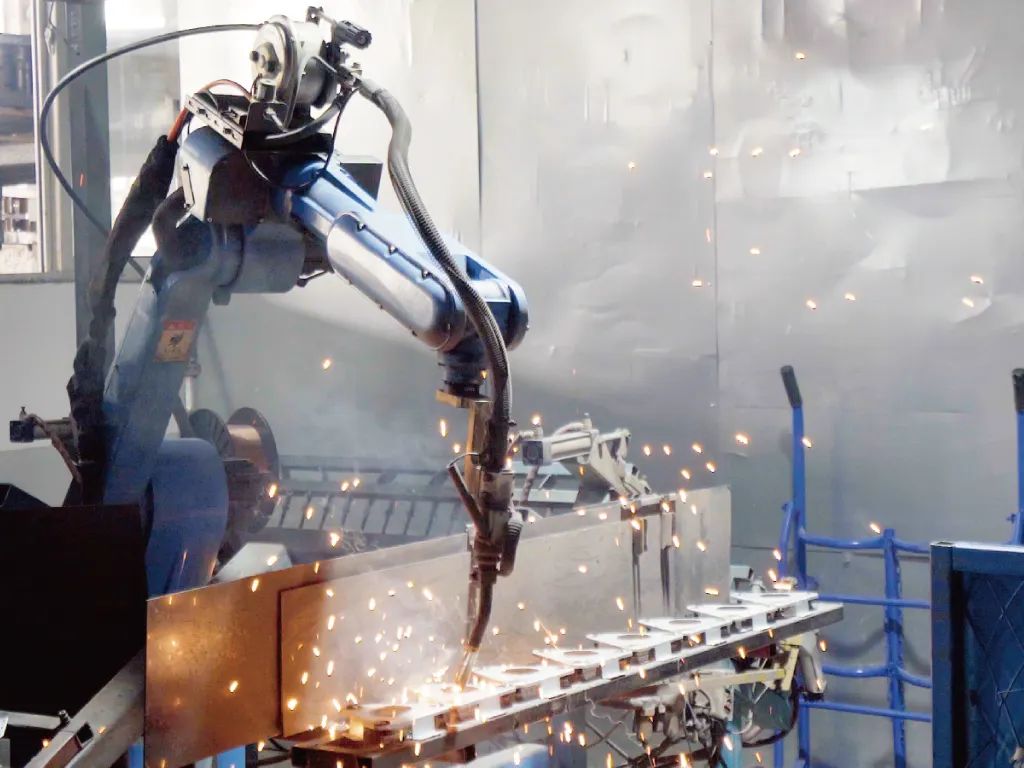

Robotic Welding

Robotic welding is the process of using an automation system to perform welding tasks. Robots can typically perform any type of welding process and complement rather than replace manual welding.

Applications: Automotive components, appliance chassis, structural frames.

JCV's automated welding solutions enhance production efficiency through:

30% faster cycle times vs manual welding

Consistency Quality control

Real-time weld monitoring systems

Dual-shift production capacity

Integrated safety protocols (ANSI/RIA R15.06)

Laser Welding

Laser cutting is a precise and surprisingly delicate welding process that uses beam light to join metal parts. It allows for extremely precise liquefaction with a much smaller heat-affected zone than any other welding method. It is particularly useful for welding materials like aluminum that are difficult to weld by traditional methods.

Ideal for battery contacts, medical devices, and precision sensors.

Our laser welding systems enable:

• <0.2mm heat-affected zone

• 50μm positioning accuracy

• Dissimilar metal joining (Al-Cu, Steel-Ti)

• Hermetic sealing for enclosures

• Pulse welding for thin-gauge materials (0.5mm+)

Spot Welding

Spot Welding (RSW) does not require filler material, and instead works by using an electrical current to generate heat. This method of welding is best suited for materials with low thermal conductivity that will generate enough conductive metal to bond the metal together. Low-carbon steel is one of the most suitable materials for Spot Welding.

Best for: Electrical contacts, heat exchanger fins, automotive panels, suit for high production volumes of parts.

Stud Welding

Stud welding is a method of joining the metal stud or similar part to a metal workpiece. Stud Welding covers a range of welding techniques including Drawn Arc Stud Welding, Short Cycle Stud Welding, and Capacitor Discharge Stud Welding, which all produce strong welds.

Stud Welding is a more flexible and economical choice than Spot Welding, and is also more versatile in the use of materials.

Applications: Insulation fasteners, threaded inserts, mounting pins

About Robotic Welding

Related Products

JCV provides one-stop service from sheet metal fabrication to welding and assembling.

Read More