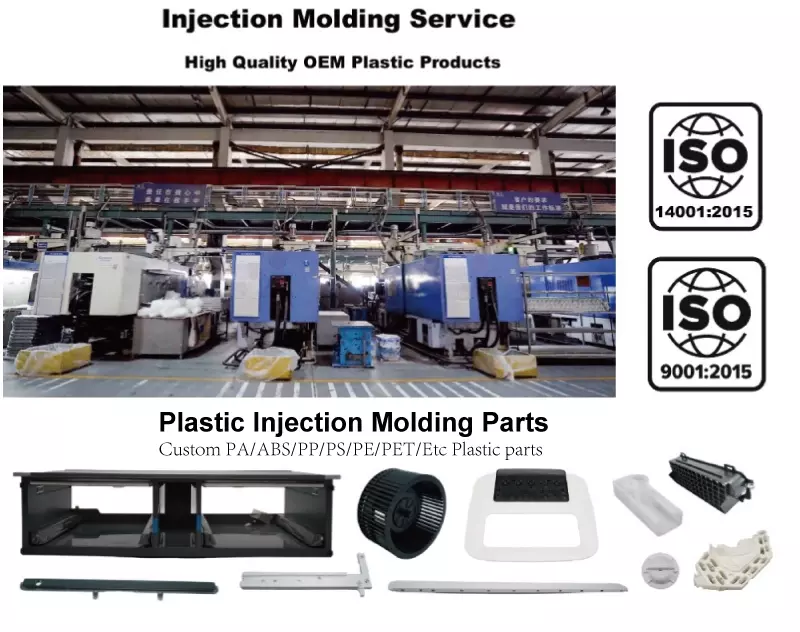

JCV Precision Manufacturing Co., Ltd. delivers 25 years of appliance housing expertise, specializing in high-volume production of washing machine enclosures with integrated molding-assembly solutions. Our 142 injection molding machine (50T-1850T) supports full-cycle manufacturing from resin pellets to ready-to-install assemblies.

Core Capabilities for Plastic Injection Molding:

▷ Multi-material capabilities:

Engineering plastics choose available (ABS/PP/PA66/PS/PE/PET/POM)

▷ 142 set injection molding machines:

With clamping force from 50ton-1850ton. Depending on the size of the product and the mold, choose the machine with the best cost.

▷ Surface enhancement options:

Brand imprinting ( Pad printing / Laser engraving / Hot transfer )

Production Workflow:

Submit 2D/3D files

Receive DFM analysis within 48hrs

Get a quotation

Sample prototyping

Sample confirm and mold trial

Launch mass production

Quality Assurance Protocols: CMM / Salt spray testing / Drop test simulation / More test as required

[Design Review] → [Mold Flow Analysis] → [Trial Run] → [Surface Treatment] → [In-line Assembly] → [Packaging]

Specialized Custom for Follow Industry Applications:

Industry | Home Appliances | Automotive industry | Industrial Equipment | Consumer Electronics |

|---|---|---|---|---|

Applications | Refrigerator door panels Air conditioner grilles Dishwasher control housings | Body shell Automotive interior shell Instrument cover | Robot arm covers Outdoor electrical box Control cabinet enclosures | Smart device outer shells Furniture Accessories Shell Wearable device frames |

Send your files now and get advice & quotes from expert engineers!

| Name | Amount | Table Travel(mm) |

| CNC Machining | 4 | 850 |

| CNC Machining | 1 | 1060 |

| CNC Machining | 1 | 1580 |

| CNC Machining | 1 | 5250 |

| CNC Machining | 2 | 4223 |

| CNC Machining | 3 | 3160 |

| CNC Machining | 2 | 2150 |

Keywords

PREVIOUS:

NEXT:

OEM Washing Machine Housing Injection Molding Enclosure Assembly

Contact Us

Classification