Our Metal Fabrication Service

Established in 2000, we are a trusted leader in sheet metal fabrication and finishing, boasting over 24 years of expertise. With our own state-of-the-art factory and R&D center, we specialize in delivering precision-engineered solutions tailored to the home appliance and automobile industry.

End-to-End Services: Prototyping, fabrication, finishing, and assembly.

Advanced Techniques: Laser cutting, CNC machining, stamping, welding, and powder coating.

Material Expertise: Steel, galvanized steel, stainless steel, aluminum, and more.

ISO9001 Certified With Excellence in Quality Metal Stamping

Total metal stamping machines

Annual production capacity

Have professional staff

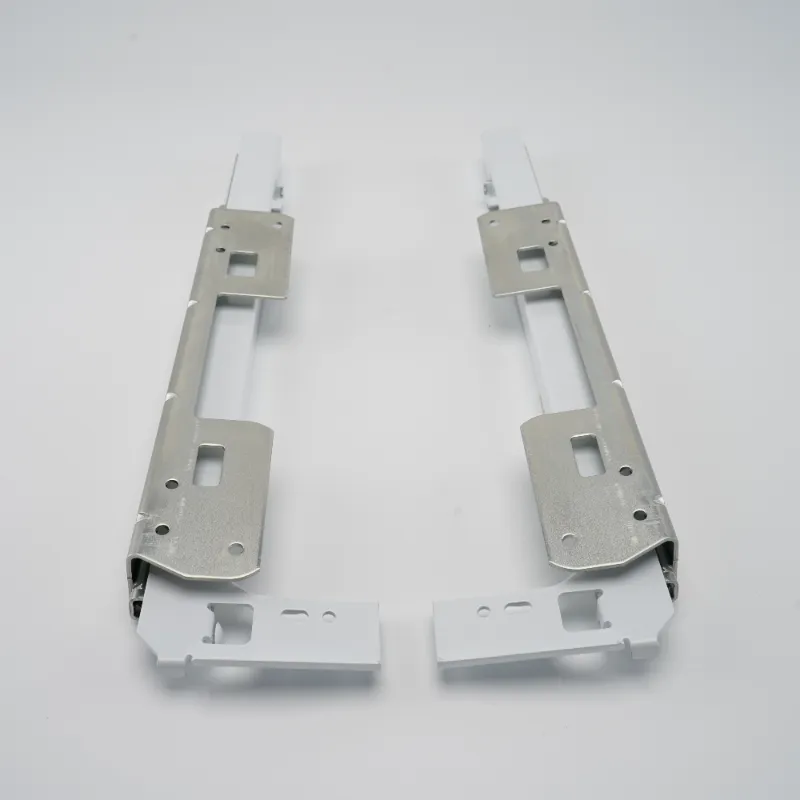

Products&Parts

Sheet Metal Fabrication

Sheet metal fabrication is the process of transforming flat sheets of steel or aluminum into metal structures or products through cutting, punching, folding, and assembling. This process includes a variety of techniques and is used to create everything from simple to complex shapes, ranging from prototypes to high-volume productions.

When combined with CNC machining or surface finishing processes like powder coating, sheet metal fabrication offers a versatile solution for industries of all types. Whether you choose progressive stamping, deep drawing, or laser cutting, sheet metal fabrication provides numerous benefits.

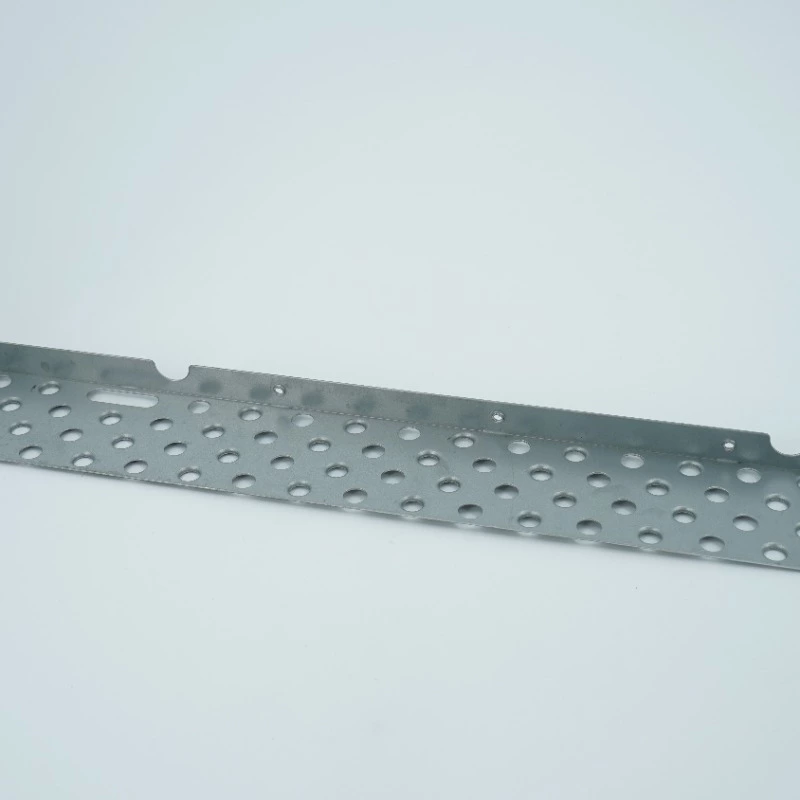

Metal Punching

Punching is one of the most efficient and cost-effective methods for adding holes and features to metal parts. It is particularly ideal for large-scale production of parts with numerous features.

At JCV, our machines can produce a wide range of holes, countersinks, embossments, louvers, and other formed features. We specialize in manufacturing high-quality parts with intricate details and complex hole patterns.

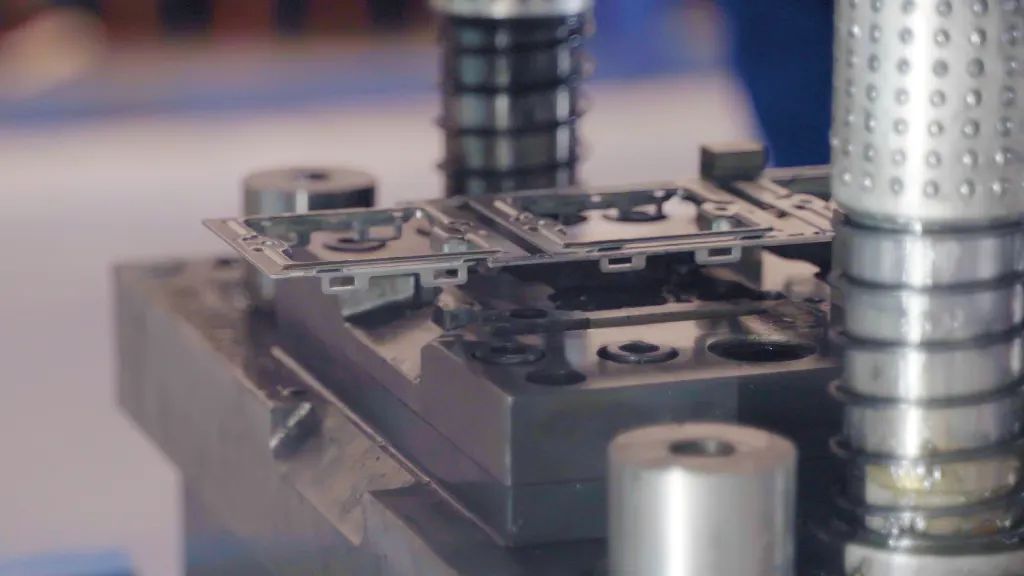

Metal Forming

Sheet metal forming is a critical component of manufacturing, and JCV is equipped to handle all your forming needs. We are committed to investing in the latest, state-of-the-art machinery to save our customers time and reduce costs.

Our automated stamping and forming machines, operated by experienced professionals, can manufacture highly complex parts with strict tolerances.

Why Choose Us?

Machine: Equipped with fully automated metal stamping lines, our maximum tonnage capacity reaches 1200T.

Scalability: Rapid prototyping to high-volume production (50,000+ units/month) with flexible MOQs.

Innovation-Driven: Our R&D center focuses on process optimization, material innovation, and sustainable practices.

Quality Assurance: ISO-certified processes with rigorous inspections to ensure durability and precision.

Reliable supply chain solutions.

Technical support for design and manufacturing

Top machinery, precision parts, on time, all the time

Large-scale rapid delivery capability

Assembly and other value-added services are available

Reliable supply chain solutions.

Products

Precision stamping of sheet metal products for household appliances and automotive components.

Core Offerings:Custom enclosures, brackets, connection/storage/functional parts, and accessories