HOW DO WE

ENSURE EXCELLENT QUALITY?

At JCV, product excellence drives our commitment to rigorous quality control and continuous improvement in precision manufacturing.

Premium Material Selection

All incoming raw materials undergo spectrometer analysis and stress testing to guarantee chemical composition compliance and structural integrity.

Certified Engineering Expertise

15+ senior engineers specializing in precision tooling and manufacturing process optimization. Each project receives dedicated engineering oversight from prototyping to final delivery.

ISO-Compliant Production Systems

We have adopted a lean manufacturing workflow in compliance with ISO9001 and ISO13485 standards, specifically designed to achieve stringent tolerances.

Multistage Inspection

JCV implements a 360° quality assurance framework: In-Process Checks / Final Assembly Audit/ Third-Party Validation

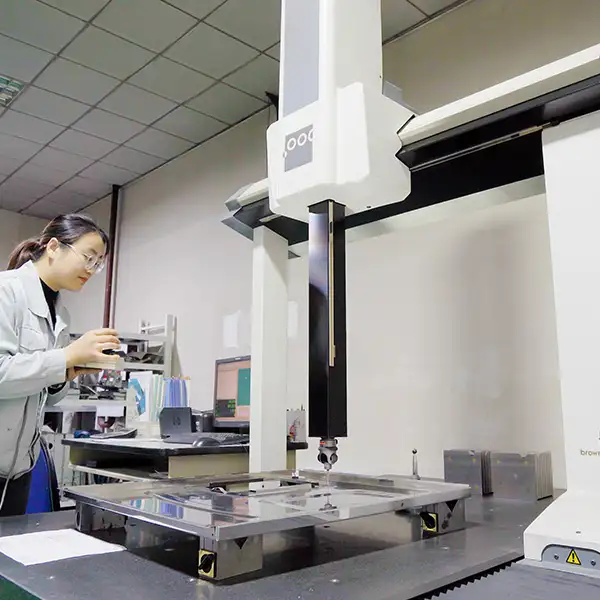

Advanced Quality Infrastructure

Own QA laboratory, multiple test device, managed by 17 certified inspectors conducting 300+ daily checks

Lifecycle Quality Management

Pre-Production: DFM analysis & risk mitigation Production: Weekly quality transparency reports Post-Delivery: Corrective action response <48hrs

Quality Inspection Steps

Quality control is a critical component of any manufacturing process. It involves inspecting and testing the raw materials, the production process, and the finished parts & product to ensure that it meets the required standards.

Material Inspection

In-Process Inspection

Comprehensive Inspection

Product Inspection

Final Inspection Report

Why Global Partners Choose JCV Precision: 98.7% first-pass yield rate | 0.15% annual defect rate | 40% repeat business rate

Cooperative customers →

Testing Device

We have a professional testing laboratory and 17 QC inspectors, from raw materials to semi-finished products to finished products.