Metal Forming Solutions

Sheet metal fabrication delivers cost-effective solutions for high-volume manufacturing. By calculated pressure through custom-engineered dies to punch, pierce, bend, and form metal substrates into dimensionally accurate components.

JCV delivers everything from basic structural panel to complex multi-axis enclosure assemblies.

Advanced Roll Forming Technology

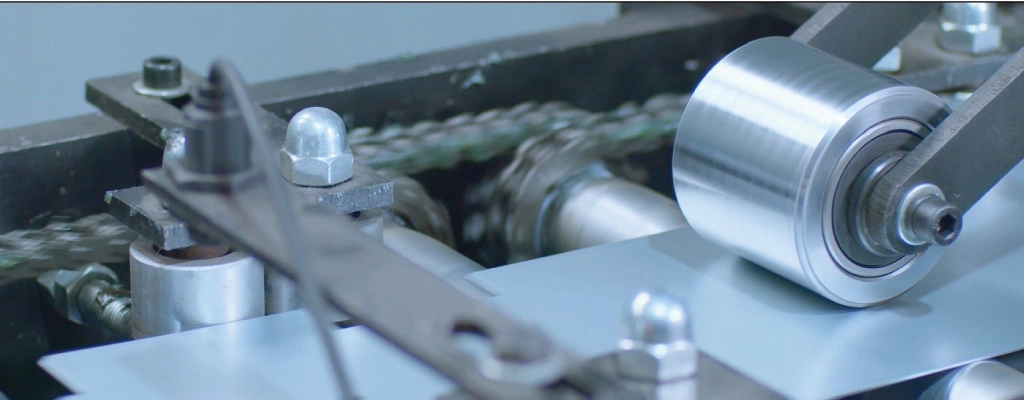

Definition: Our continuous roll forming process transforms steel/aluminum/stainless steel into engineered shape through progressive forming stations. Each roller set applies controlled incremental deformation to achieve complex cross-sections while maintaining material integrity.

Feature: The unique aspect of this approach is the use of consecutive forming stations, each of which nudges the metal toward the desired shape. Based on the targeted profile, a computer calculates the optimal placement and shape of the rollers for maximum efficiency and designs the track. The more advanced the desired shape, the more rollers the material goes through. The roll-forming line can bend metal, and form metal into tubes, and beams.

Smart Roll Forming Production Systems

JCV operates 5 fully automated roll forming production lines specializing in refrigeration beam components.

We independently researched and developed this technology and have our invention patent (CN213469268U).

Revolutionizes Manufacturing Process

Our self-developed intelligent forming systems have redefined beam parts manufacturing standards for global partners, achieving:

- 100% pass rate VS traditional 92%-98% industry average

- Surface flatness improvement: ≤ 0.3mm

- Production cycle reduction: 8-step → 1-step process

Metal Forming

Products

We use automatic stamping machines and roll forming line to process sheet metal parts for home appliances, such as refrigerator parts, washing parts, air conditioning parts, etc.

undefined