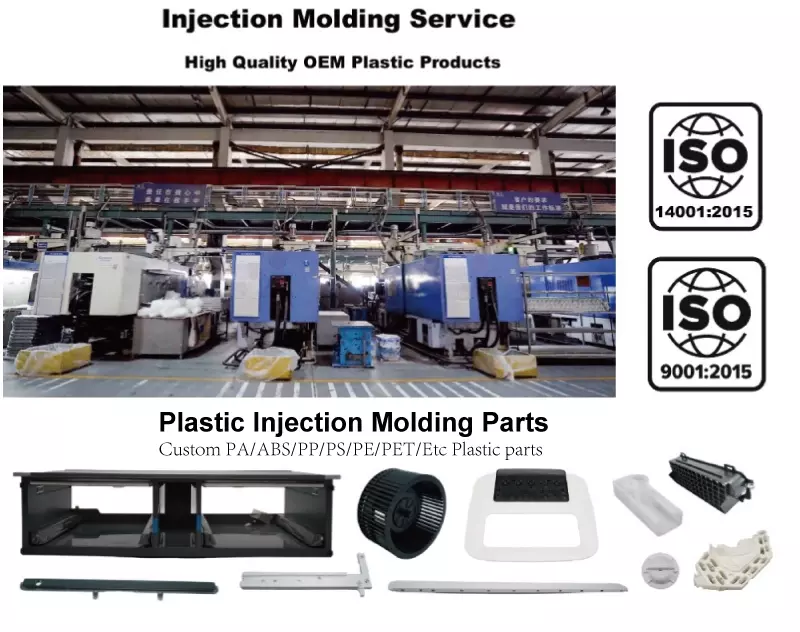

JCV specializes in high-precision injection molding for oversized appliance panels, with particular expertise in HVAC system components, refrigerator parts, washing machine parts. Our 1850-Ton clamping force injection molding machine enables production of panels up to 2m in length.

Core Capabilities for Appliance Panel Components Production:

▷ 50-1850T injection molding machines with dedicated large assembly stations;

▷ 2M+ annual capacity for white goods panels (refrigerator/washer/AC fronts);

▷ A-class surface finishing (Ra0.8μm~Ra3.2μm);

▷ In-house post-processing center for:

• Electroplating (chrome/nickel finishes)

• Branding services (screen printing, Laser engraving, thermal transfer printing)

• Assembly

Project Workflow:

[Design Consultation] → [Mold Flow Analysis] → [Sampling] → [Pilot Run] → [Full Production]

Why Partner With JCV?

✔ 25-year track record in appliance panel manufacturing;

✔ 142 injection molding machine for different project;

✔ Dedicated cleanroom production for transparent parts;

✔ Triple inspection system;

Submit your panel specifications through email for instant DFM feedback and volume pricing. On-site mold inspection available at our Qingdao facility by appointment.

| Name | Amount | Table Travel(mm) |

| CNC Machining | 4 | 850 |

| CNC Machining | 1 | 1060 |

| CNC Machining | 1 | 1580 |

| CNC Machining | 1 | 5250 |

| CNC Machining | 2 | 4223 |

| CNC Machining | 3 | 3160 |

| CNC Machining | 2 | 2150 |

Keywords

PREVIOUS:

NEXT:

Custom Large-Format Injection Molding ABS PS Appliance Panels

Contact Us

Classification