Understanding Hot Runner Injection Molds: Revolutionizing Manufacturing Efficiency

Jun 20,2025

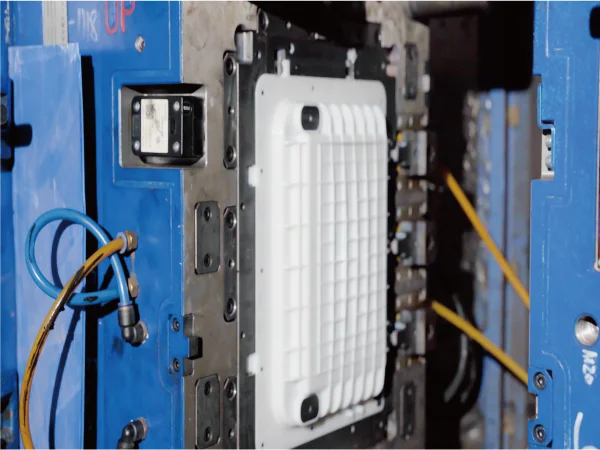

Hot runner injection molds are an innovative technology in the realm of manufacturing, particularly in the field of plastic injection molding. Unlike traditional cold runner systems, hot runners maintain the plastic in a molten state as it flows through the mold, which significantly enhances the efficiency and quality of the molding process.

One of the primary advantages of hot runner systems is their ability to reduce material waste. In conventional cold runner systems, excess plastic that does not fill the mold cavity is often discarded. This not only leads to increased costs but also contributes to environmental waste. Hot runners mitigate this issue by recycling the excess material, as it remains in a heated state and can be reused in future cycles. This efficiency not only lowers production costs but also aligns with sustainable manufacturing practices, making it an attractive option for companies looking to optimize their processes.

Moreover, hot runner injection molds facilitate shorter cycle times. Since the material is kept heated and ready to flow, the time required for the material to cool down and solidify is reduced. This means manufacturers can produce more parts in less time, thus increasing overall productivity. Additionally, the consistent temperature of the molten plastic leads to improved part quality, as there is a lower risk of defects such as warping or incomplete filling.

Another important feature of hot runner systems is their ability to allow for intricate designs and complex geometries. The technology supports multi-cavity molds, enabling the simultaneous production of multiple parts. This is particularly beneficial in industries requiring high-volume production where precision and uniformity are critical.

However, while hot runner injection molds offer numerous benefits, they also come with certain challenges. The initial investment for hot runner systems can be higher compared to cold runner alternatives. Additionally, the complexity of the system may require specialized training for operators and maintenance personnel to ensure optimal performance.

In conclusion, hot runner injection molds represent a significant advancement in the field of manufacturing, particularly within the injection molding process. Their ability to enhance efficiency, reduce waste, and improve product quality makes them an invaluable asset for modern production facilities. As industries continue to evolve, adopting technologies like hot runner systems will be crucial for companies aiming to stay competitive in a fast-paced market. Understanding the functionalities and benefits of hot runner injection molds can equip manufacturers with the knowledge needed to make informed decisions about their production processes and technological investments.