Unlocking the Benefits of Rapid Prototype Machining in Electronics Manufacturing

Sep 04,2025

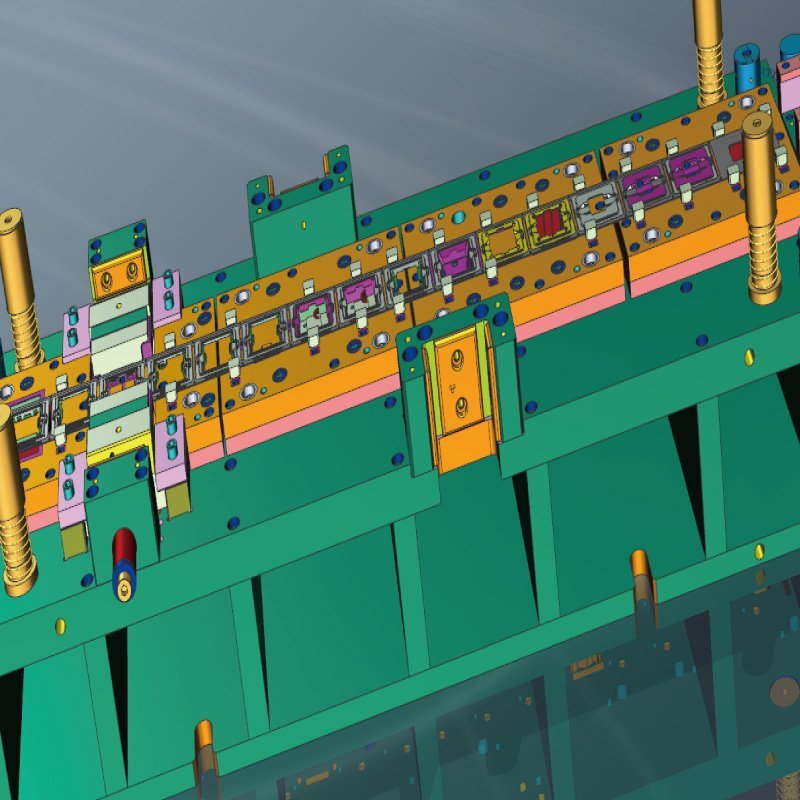

Rapid prototype machining is a cutting-edge process that significantly impacts the electronic components manufacturing industry. It involves creating precise prototypes of electronic parts rapidly, allowing engineers and designers to validate their concepts and designs before full-scale production. This method is particularly beneficial in the fast-paced world of electronics, where time-to-market is critical.

One of the primary advantages of rapid prototype machining is its ability to reduce lead times. Traditional prototyping methods can take weeks or even months, delaying product release and increasing costs. However, with advanced machining technologies such as CNC (Computer Numerical Control) machining and additive manufacturing, prototypes can be produced in a matter of days. This speed allows manufacturers to quickly iterate designs based on testing and feedback, leading to more refined and effective products.

In addition to time savings, rapid prototype machining offers enhanced accuracy and detail. The sophisticated equipment used in this process can create intricate designs with tight tolerances, which is essential for electronic components that require precise fitting and functionality. This level of precision ensures that prototypes are not only visually accurate but also functionally reliable, which is crucial for the testing and validation phases of product development.

Moreover, rapid prototype machining enables better collaboration between design teams and stakeholders. With tangible prototypes in hand, teams can conduct more effective reviews, gather feedback, and make informed decisions about design adjustments. This collaborative approach helps in identifying potential issues early in the development cycle, reducing the risk of costly changes during production.

Sustainability is another important aspect of rapid prototype machining. By optimizing material usage and reducing waste, this method aligns with modern manufacturing's push towards more environmentally friendly practices. Engineers can experiment with different materials and processes without the extensive waste that traditional methods often produce, contributing to a more sustainable production cycle.

Finally, rapid prototype machining fosters innovation within the electronic components sector. The ability to quickly test and refine ideas creates an environment where creativity can flourish. Engineers are empowered to explore new concepts and technologies without the fear of significant financial investment in initial production runs.

In conclusion, rapid prototype machining is revolutionizing the electronic components manufacturing industry. Its ability to expedite the prototyping process, enhance accuracy, facilitate collaboration, promote sustainability, and encourage innovation makes it an indispensable tool for manufacturers. As the demand for faster and more efficient production grows, embracing rapid prototype machining will be crucial for staying competitive in the evolving landscape of electronics manufacturing.