Unlocking Efficiency: The Role of Multi-Cavity Injection Molding in Plastic Parts Production

Aug 26,2025

Multi-cavity injection molding has emerged as a pivotal process in the realm of plastic parts production, an innovative technique that allows manufacturers to produce multiple identical components in a single cycle, enhancing productivity and minimizing costs. As industries increasingly demand precision and efficiency, understanding the mechanics and advantages of multi-cavity injection molding becomes essential for manufacturers. To grasp its value fully, it is first important to understand the basics of injection molding itself—a manufacturing process where molten plastic is injected into a mold cavity, allowing it to cool and solidify into a specific shape. This method is celebrated for its ability to create complex geometries and achieve high levels of precision, yet traditional single-cavity molding methods may not meet the rapid production needs of today’s market, which is where multi-cavity injection molding shines.

Multi-cavity systems provide several key advantages over traditional methods, starting with increased production efficiency: by utilizing multiple cavities within a single mold, manufacturers can produce more parts in less time, a crucial capability for meeting high-volume demands without compromising quality. The reduced cycle time not only speeds up production but also enables quicker turnaround on orders. Alongside efficiency comes cost reduction benefits—producing several parts simultaneously significantly lowers the cost per piece, helping businesses offer competitive pricing while maintaining profitability, and the efficient use of materials also minimizes waste to further drive down costs. Additionally, multi-cavity systems offer enhanced design flexibility, accommodating various shapes and sizes so designers can experiment with different geometries without the need for multiple molds, streamlining the prototyping process and expediting the introduction of new products to market.

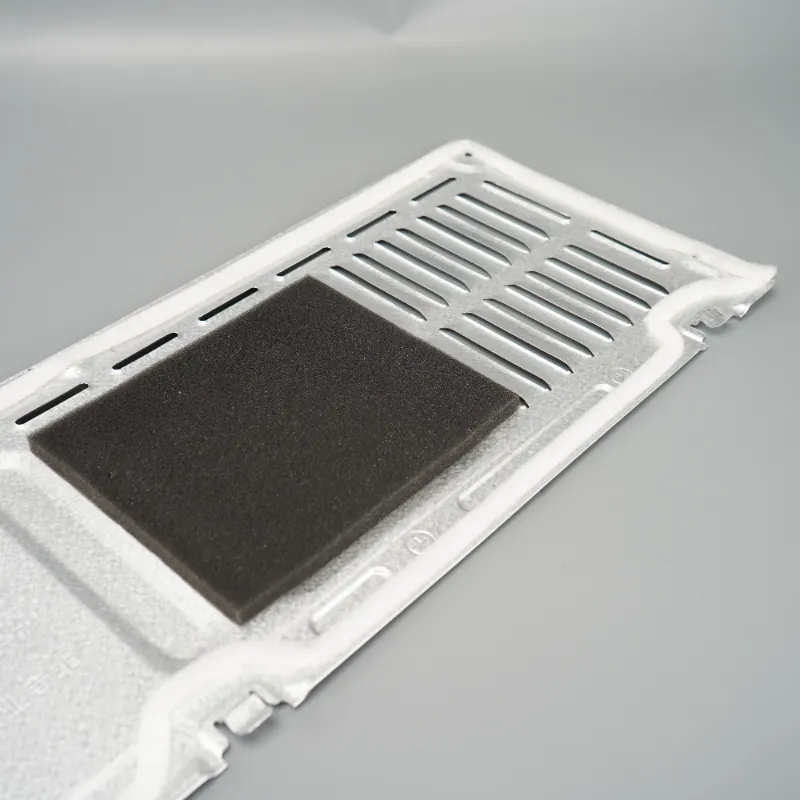

Understanding the key components of multi-cavity injection molding is essential for optimizing production, with mold design being critical in such systems. Engineers must ensure each cavity is evenly filled and that cooling times are consistent across all parts, and advanced simulation software can aid in optimizing mold design to reduce the risk of defects. The injection unit is another vital component, as it must be capable of delivering the required volume of material quickly and consistently—proper sizing and calibration are necessary to ensure uniform injection pressure across all cavities, preventing variances in part quality.

To maximize the benefits of multi-cavity systems, several best practices should be followed, beginning with material selection. Choosing the right material is crucial for achieving desired mechanical properties and ensuring compatibility with the mold design, and factors like melt flow index and thermal properties must be considered to prevent issues during production. Process optimization techniques are also important: optimizing the injection molding process involves adjusting parameters such as temperature, pressure, and cooling time based on the specific requirements of the parts being produced, and continuous monitoring and adjustments can prevent defects and enhance overall efficiency.

Multi-cavity injection molding is utilized across various industries due to its versatility. In consumer products, from household items to packaging, high-volume production of items like bottles, containers, and toys leverages the efficiency of multi-cavity molding to meet consumer demand while maintaining low costs. The medical industry, where precision is paramount, relies on this method to produce intricate components for devices such as syringes and surgical tools, ensuring adherence to stringent quality standards. Automotive manufacturers also depend on multi-cavity molding for producing lightweight and durable components like dashboard parts and housings, as the ability to produce multiple parts simultaneously accelerates the assembly process and reduces lead times.

Despite its advantages, multi-cavity injection molding presents certain challenges, including uneven cooling, potential for defects, and the complexity of mold design. Addressing these challenges requires careful planning and skilled engineering. Looking ahead, as technology evolves, so do the capabilities of multi-cavity injection molding—advancements in materials, automation, and process control are set to enhance efficiency further, pushing the boundaries of what can be achieved in plastic parts production. Innovations such as smart molding and 3D printing integration are on the horizon, promising to revolutionize the industry.

PREVIOUS: