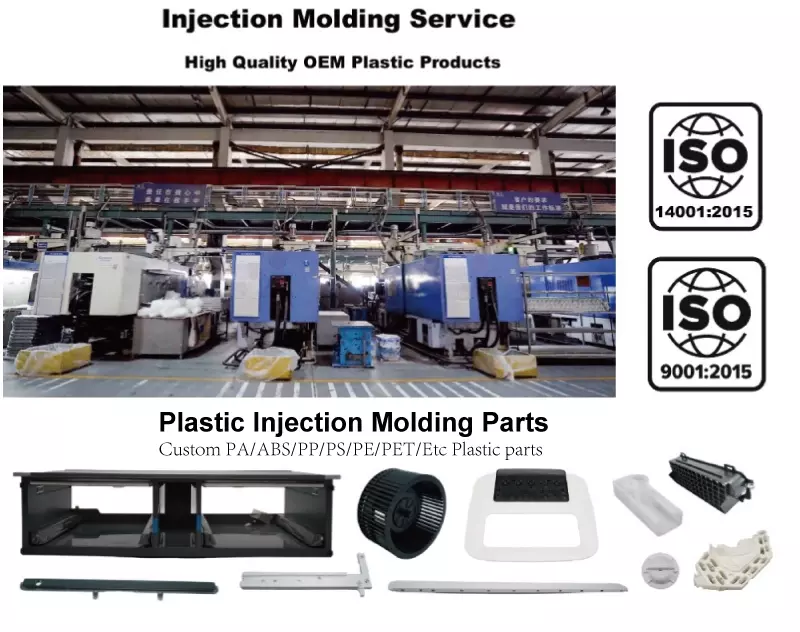

JCV Precision Manufacturing excels in the injection molded appliance parts. With over 26 years of experience in plastic injection molding, we are well-equipped to manufacture intricate plastic components—including housings, casings, shells, brackets, boxes, panels—suitable for residential, industrial, and commercial applications.

End-to-End Solutions:

We handle the entire process under one roof:

- Design for Manufacturability (DFM) Feedback

- Precision Mold Making & Validation

- Injection Molding Production

- Secondary Operations (Assembly, Pad Printing, Laser Marking)

- Stringent Quality Control (Including Full Test Support)

- Packaging & Logistics

Reliability & Compliance Appliance Makers Demand:

Proven Track Record: Decades of supplying durable components for consumer and industrial appliances like Haier.

Rigorous Quality Systems: ISO 9001:2015 certified processes. In-process inspections and final AQL checks.

Material Compliance: Expertise in sourcing resins meeting RoHS, REACH, FDA (as applicable), and specific OEM standards.

How We Collaborate?

Share Your Requirements: Provide sketches, CAD models (STEP, IGES), samples, or specifications.

Collaborative Engineering: Our experts review for manufacturability and optimize for cost/performance.

Prototype & Approve: Rapid prototyping available (3D Printing, Soft Tooling) for form/fit/function verification.

Precision Tooling: High-quality mold construction for longevity and part consistency.

High-Efficiency Production: Multi-cavity molding for your volume needs.

Quality Assurance & Delivery: On-time delivery of parts meeting your exact standards.

Ideal for: Major Appliance OEMs, Control Panel Manufacturers, Industrial Equipment Makers.

Ready to Get Your Custom Plastic Parts Produced?

Request a Quote Now!

No MOQ? Ask us about our flexible solutions for startups and pilot projects!

PREVIOUS:

NEXT:

OEM Plastic Components Appliance Injection Molded Housings

Contact Us

Classification